Stable & Optimized Supply

In this age of ever-intensifying energy supply and demand, a stable supply of products is a key factor in the development of a national economy. S-OIL has built an optimized supply system that ranges from oil imports to production, transportation, and sales, achieving unparalleled operational efficiencies in the process.

Ensuring a Stable Supply of Crude Oil

In February 2012, S-OIL renewed a 20-year-long crude purchase agreement with Saudi Aramco, the principal shareholder of Aramco Asia that is the major shareholder of SOIL, and the national oil company of the world’s biggest oil producing country, Saudi Arabia. The long-term agreement is a rare occasion in the crude oil market, where one-year contracts are common. The signing of the deal is credited to the long-term partnership between Saudi Aramco and SOIL, which has lasted for over 20 years since the first contract in May 1991, and the long-standing and amicable relationship between Korea and Saudi Arabia.

This means that the company was able not only to secure a steady and long-term source of feedstock but was also able to supply energy to the global community in a stable and economical manner. Given Korea’s high dependence on oil, reducing these risks plays an important role in national energy security. In addition, the company’s production facilities are best suited to refining crude imported from Saudi Aramco, enabling S-OIL to produce high value-added products in an economical and efficient way. By doing so, we can supply products to our domestic and international customers at highly competitive prices, an unrivaled core capability of the company.

◆ Crude oil processed unit : thousand barrels

Crude oil processed : 2010 ~ 2015 years Table.

| 2011 |

2012 |

2013 |

2014 |

2015 |

| 218,714 |

232,812 |

216,246 |

227,462 |

219,680 |

Production

S-OIL developed upgrading facilities to produce high value- added products much earlier than its competitors. Our capital expenditures are used to augment the efficiency of our operations and keep our equipment in peak condition to stably produce and supply the optimized products.

Capital Expenditure to Optimize Manufacturing Process

In order to improve the quality standards of our gasoline and enhance our profitability, we invested a total of 135 billion won to build a plant that can produce Alkylate, the raw material for premium gasoline. We also completed the construction of the second Aromatic Complex in the first half of 2011 where we invested more than 1.3 trillion won through 3 years of planning, design, and construction and began its commercial operation.

The expansion of facilities allowed us to secure a proper loading and supply system to accommodate changed conditions such as an increase in production and exports. We also spent 46 billion won in 2009 on building a new pier with a capacity of 50,000 tonnes. This enabled us to prepare for a global trend towards bigger vessels. It also made shipping more stable and smoother, helping us reduce the costs of pier rentals. Our need to reserve piers for our own use also decreased, lowering the demurrage rate.

Maintaining Equipment for Stable Operations

S-OIL has devised systematic maintenance strategies to ensure that it has a world-class equipment maintenance system. A new program called “Risk-Based Inspection” has been in place since 2011. It manages equipment based on its reliability and the risk of defects, allowing for systematic interactions and feedback between the company’s production and maintenance workers and letting the company manage its human and material resources more efficiently. By doing so, it increases the reliability of the machinery, ensures the stable operation of the plant with optimized management costs. We have a separate preventative maintenance team besides the maintenance performance team to develop sophisticated maintenance and diagnosis technology and to invest actively in preventative maintenance.

The preventative maintenance team pursues enhancing equipment reliability, which means maintaining the equipment’s functions without failures, by reinforcing preventative maintenance strategies for operators in the production sector. By doing this, we keep the plant operating more stably, and are able to extend our maintenance cycles, improving management efficiency. In addition, we establish a periodic maintenance plan every year by managing such factors as safety, quality, and the scheduling of key maintenance work. We try to complete it in the shortest possible time. These efforts have resulted in a high mechanical availability and significantly reduced maintenance costs. S-OIL is carrying out a specialized assessment on maintenance to establish strategies for improvement and develop state-of-the-art techniques. We make our best efforts to become capable of operating plants under any circumstances.

Advanced Operating Systems

S-OIL’s advanced operating systems are designed to maximize the efficiency of all its procedures: its process automation, environmental management, and customer support systems. The company is strengthening its competitiveness through the optimization of business process and the consistent improvement of the operating systems.

Strategic Performance Management

S-OIL’s strategic performance management system allows its employees to set strategic targets for major market changes and business issues, share them with their co-workers, and take appropriate action. Strategic performance management is a system that uses KPIs (Key Performance Indicators) to help an organization perform tasks that are necessary to achieve its goals.

In order to realize the Company’s Grand Vision, S-OIL developed nine Corporate Initiatives (CI) as mid-to long-term initiatives in 2013. The nine CIs were specifically allocated to the KPIs of all officers, and their accomplishments on KPIs will be monitored on a regular basis. If necessary, catch-up plans will be established. As such, the Company has revamped the entire process of strategy implementation, from setting strategies to implementation, monitoring and further to evaluation and compensation.

Upgrading the ERP System & Establishing IFRS

Management changes often require improvements to various processes. S-OIL is constantly enhancing its infrastructure to cope with such requirements in a timely manner, thereby increasing the efficiency and flexibility of all its work processes. We introduced ERP(Enterprise Resources Planning) system in 2006, and it has been a ma jor part of infrastructure since then. We upgraded the system to respond to internal and external management changes. The upgraded version has been in operation since January, 2010.

This upgrade perfectly prepared for the mandatory introduction of IFRS (International Financial Reporting Standards) in 2011. We focused on improving our ERP system to meet the requirements for IFRS. For example, we changed our methods for managing tangible assets, evaluating inventories, and preparing financial statements.

Enhancement of Operational Excellence

Global oil business is faced with increasingly fiercer competition due to the emergence of shale gas and facilities expansion in regions like the Middle East, India, and China. Furthermore, the prolonged drop in oil price since mid-2014 is intensifying the uncertainties of the business environment. Amidst these adverse conditions, S-OIL endeavors to achieve operational excellence and cut energy consumption, thereby improving the Company’s bottom-line and ultimately its competitive edge.

Activities to Achieve Operational Excellence

S-OIL carries out a variety of programs aimed at sharpening its competitive edge through operational excellence. The Company implemented profit improvement campaign where all employees voluntarily participated, and organized weekly idea meetings to explore what can be done to increase profits. The ideas collected from the meetings were thoroughly scrutinized before being implemented with real-time monitoring via refinery information systems, ensuring total accuracy. In addition, S-OIL expanded its reward program for energy saving, in place since 2011, to cover all profit improvement activities and dramatically increased prize money, increasing the incentive for profit improvement. Moreover S-OIL identified a total of 229 items for profit improvement through cooperation with an external specialized agency in 2014.

As of 2015, a total of 46 new items were identified for profit improvement from increased production of high value added products, energy saving, and optimization of product delivery. The profit improvement that S-OIL achieved through these efforts is estimated at about KRW 190 billion a year, including the rise in production yield rate.

Cost Reduction from Energy Exchange Projects

Since July 2014 when S-OIL was designated as an integrated energy supplier, we have engaged in the power generation business using waste heat. We also cooperated with nearby companies in energy exchange projects, laying the foundation for cost reduction.

S-OIL has diversified sourcing channels of external energy to become more flexible in responding to fluctuating oil prices: we introduced low cost steam from LS-Nikko Copper in 2008 and then from Korea Zinc Company in late 2014. By generating electricity with waste heat and recycling resources, we expect to curtail 61,000 tons of greenhouse gas emissions annually, equivalent to environmental protection efforts of planting more than 9 million 30-year-old trees. In addition, by generating electricity sufficient to power 7,000 households a year and increasing the electricity power reserve rate through distributed power generation, we contributed to alleviating electricity shortages during summer and winter months.

Safety & Health Prioritizing Management

A company’s sustainable growth requires diverse efforts on multiple fronts from productivity improvements to quality control. However, what comes first and foremost is safety, and creating a zero-accident worksite is essential to business continuity.

S-OIL’s endeavors to ensure safety for workers encompass the entire process from planning to design, construction, maintenance, and repair. Furthermore, in other pre-emptive attempts to avert fire or explosion that may affect not only our workers but also local communities, S-OIL carries out a wide range of safety management activities.

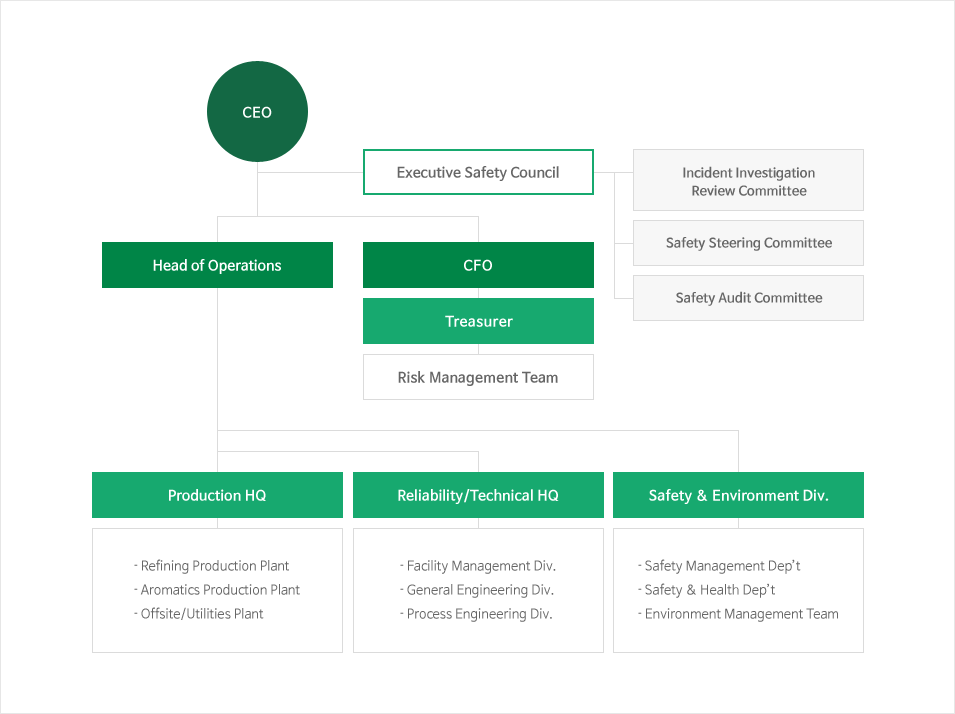

Safety Management Organization

For the purpose of putting in place world’s top safety culture and establishing accident free worksites, S-OIL has been operating the Executive Safety Council that reports to the CEO and 3 sub-committees of Safety Steering Committee (SSC), Incident Investigation Review Committee (IIRC) and Safety Audit Committee (SAC) under the council.

The committees ensure that the top management stays aware of the latest safety issues and makes well-informed decisions. Additionally, the Company operates Safety & Environment Division, Safety Management Department, and Safety & Health Department under the oversight of Head of Operations with a mandate to control safety and promote safety culture at work sites. In addition, S-OIL set up the Risk Management Team under the direction of the CFO in order to prevent and take pre-emptive actions against risks

CEO

- Executive Safety Council

- Incident Investigation Review Committee

- Safety Steering Committee

- Safety Audit Committee

- Head of Operations

- Production HQ

- - Refining Production Plant

- - Aromatics Production Plant

- - Offsite/Utilities Plant

- Reliability/Technical HQ

- - Facility Management Div.

- - General Engineering Div.

- - Process Engineering Div.

- Safety & Environment Div.

- - Safety Management Dep’t

- - Safety & Health Dep’t

- - Environment Management Team

- CFO Treasurer Risk Management Team

Safety Management System

S-OIL is the first refiner in Korea to introduce the Occupational Health and Safety Management System (KGS/OHSAS 18001) and obtained certification in 2007. We also established the Integrated Information Management System for SHE in 2008, a web-based platform to integrate Safety, Health, and Environment into a single system. This system facilitates the decision-making process and efficient operations through systematic information sharing. In addition to this, we put in place the Behavior-Based Safety (BBS) program in 2013 to analyze unsafe behaviors and address potential risk factors.

Behavior Based Safety (BBS) Program

Behavior-based Safety (BBS) is a program that analyzes the unsafe behaviors of workers to take corrective measures in a systematic way. Under this program, all employees at worksites are required to identify at least two unsafe behaviors or cases each month. Officers then should ensure that the corrective measures are taken based on the risk assessment. In 2015, a total of 28,678 unsafe cases were reported and shared among all employees at worksites, which led to the elimination of potential risk factors.

Acquisition of Safety Zero Certification

In 2012, S-OIL became the first domestic refiner to acquire the Safety Zero Certification. Supervised by the National Emergency Management Agency and provided by the Korea Safety Certification Institution, this certification is Korea's only fire protection evaluation system that assesses and certifies the maintenance, management, and operation of fire protection systems. The Safety Zero Certification is an objective proof of S-OIL's outstanding fire safety management capabilities. In addition, through its continued maintenance efforts regarding its fire fighting facilities and disaster prevention activities, the company implemented a system that ensures a systematic response to emergencies.

Safety-first Culture at the Workplace

In October 2013, with the aim of encouraging employees to join the initiative of establishing disaster free worksites and raising awareness about safety rules, S-OIL proclaimed ‘Safety Golden Rules’ that all employees at both S-OIL and its partner companies should abide by.

In 2014, S-OIL laid more stress on safety performance within KPI measurements to reinforce the responsibility of all executive officers for safety management. We also continue to benchmark safety management systems of global corporations, thereby promoting a culture of safety to take firm root company-wide.

Management Safety Inspection

In accordance with the company’s business philosophy that “safety is the number one priority in all business activities,” S-OIL’s top management is at the forefront of promoting a culture of safety; for example, it conducts regular safety walkthroughs at the sites. Such involvement of top management conveys a clear message to all S-OIL employees that safety is the number one priority. As part of these endeavors, the company reflects the safety KPI in the performance records of all executives and managers, including those in charge of operation. It is also strengthening its commitment to safety by inserting the phrase “Safety First” in all of its documents.

As part of S-OIL’s practical activities to promote safety culture, all meetings in the Operations begin with a safety talk. In addition, biweekly meetings attended by the CEO and executive officers begin with presentations on safety tips, followed by a lively discussion on the subject to reaffirm top management’s commitment to safety management.

Safety Culture Score Management

S-OIL checks and manages the track of Safety Culture Score that evaluates employees' awareness of safety and reflects the results when drafting safety rules and policies. In the 2015 assessment, the score was 7.4 or 'Leading Edge', meaning that its safety culture stood at the upper middle grade.

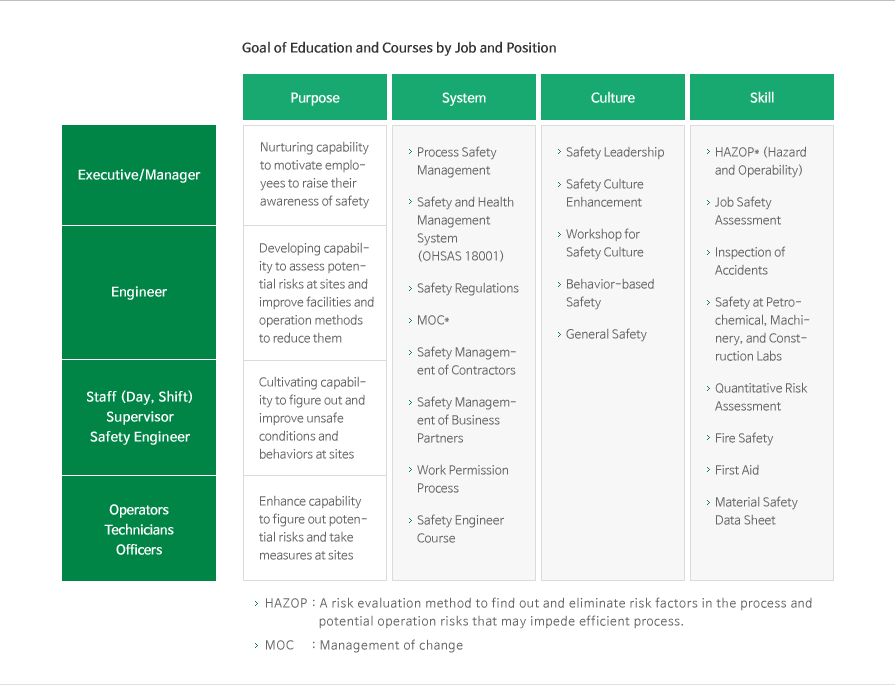

Safety, Health Education and Training

S-OIL emphasizes the importance of safety education for accident prevention, and runs regular safety education and training sessions for both managers and employees to determine the best response strategies if accidents occur. We hold training on internal safety and health education as mandated by the Industrial Safety and Health Act, special education on 39 dangerous operations including hypoxia, new employees education, monitoring supervisors education, and basic safety rules education for the workers of partner companies. We also provide safety and health improvement education to both S-OIL’s employees and to employees of partner companies.

S-OIL started providing 27 educational courses for the entire workforce according to their positions and roles in 2014. The goal of this tailored program is to raise the awareness of safety, and ultimately to establish a world-class safety culture. A total of 4,163 employees completed 17 courses in 2015 and the figure will be extended to 5,020 in 22 courses in 2016.

Goal of Education and Courses by Job and Position

Goal of Education and Courses by Job and Position : Purpose, System, Culture, Skill Table.

|

Purpose |

System |

Culture |

Skill |

| Executive/Manager |

Nurturing capability to motivate emplo-yees to raise their awareness of safety |

Process Safety

Management

Safety and Health Management System (OHSAS 18001)

Safety Regulations

MOC*

Safety Managem-ent of Contractors

Safety Managem-ent of Business Partners

Work Permission Process

Safety Engineer Course

|

Safety Leadership

Safety Culture Enhancement

Workshop for Safety Culture

Behavior-based Safety

General Safety

|

HAZOP* (Hazard and Operability)

Job Safety Assessment

Inspection of Accidents

Safety at Petro-chemical, Machi-nery, and Const-ruction Labs

Quantitative Risk Assessment

Fire Safety

First Aid

Material Safety Data Sheet

|

| Engineer |

Developing capabil-ity to assess poten-tial risks at sites and improve facilities and operation methods to reduce them |

| Staff (Day, Shift) Supervisor Safety Engineer |

Cultivating capabil-ity to figure out and improve unsafeconditions and behaviors at sites |

| Operators Technicians Officers |

Enhance capability to figure out poten-tial risks and take measures at sites |

HAZOP : A risk evaluation method to find out and eliminate risk factors in the process and potential operation risks that may impede efficient process. , MOC : Management of change

Partner Company Safety Management

S-OIL has formed a consultative body with business partners to share its advanced safety culture practices. The consultative body convenes for regular safety meetings once a month and carries out collective inspection on a quarterly basis. We also offer a wide range of safety-related programs such as special lectures on safety culture and risk evaluation education.

In addition, S-OIL provided technological and financial supports for business partners, helping three of them to be accredited with OHSAS 18001 in 2015.

S-OIL's continued support for its business partners on safety management has resulted in the Company earning the A-Grade from the Government in the evaluation of shared growth programs in 2015 and winning the Korea Occupational Safety and Health Agency President's Award in the shared growth presentation contest.

Preventative Green Management

“Preventative Green Management” means preventing hazardous environmental elements and dangers in every step of every operation. S-OIL practices green governance to protect the environment through the use of our highly advanced environmental operation system.

Environmental Management System

S-Oil puts preemptive green management practices at the top of its environmental policy list. As it continues to innovate its processes and environment-related facilities, the Company also adopts new techniques to produce eco-friendly products on a continual basis. In fact, it has been introducing desulfurization and denitrification facilities, cutting-edge wastewater treatment facilities, and precipitation facilities for years.

In 1996, S-OIL acquired the ISO 14001 (certification for Environmental Management Systems) on all its production processes for fuel oil, lube base oil, and petrochemical products. Since then, the certificate has been renewed five times. S-OIL practices high level environmental management through regular reviews in accordance with the Company’s unique business environment, and constantly develops and improves its Environmental Management System (EMS). With the introduction of the ISO 14031, the Company’s EMS has successfully taken root within the organization, which is also publishing annual SHE (safety, health, and environment) report and sustainability report. The Company is now further developing its EMS and has recently implemented an independent Environmental Accounting (EA) system. In 2013, its terminals in Incheon, Yeongcheon and Gunsan obtained the ISO 14001 certificate, completing full and comprehensive EMS control over the Company’s entire production process.

Working-level Environmental · Safety Council

S-OIL has set forth the roles and responsibilities of environmental · safety activities to enhance efficiency. In particular, the Working-level Environmental · Safety Council, which consists of environmental · safety officers from the Head Office and the Onsan Refinery, plants, terminals, and service stations, ensures a company-wide integrated response and effective approach to any environmental and safety issues.

The Council reviews and deliberates various environmental issues that may arise at each stage of the value chain, from production, distribution · logistics and sales to marketing and purchasing, to set policies that are most relevant to the company’s business directions. Its main functions are to proactively put the company’s commitment to environmental · safety management into action at each and every of its business sites. More importantly, the Council speaks for the company in the Korean government’s policy-making procedures.

Environmental Performance Evaluation System (ISO 14031)

S-OIL has established a standard Environmental Performance Evaluation (EPE) system under ISO 14031 guidelines in order to objectively assess its environmental investments and activities, and to reflect assessment results in subsequent environmental management plans. EPE refers to procedures that range from listing environmental indicators and regularly collecting and analyzing environmental data to reviewing and improving environmental performance to reflect all results in future decision- making by top management and stakeholders.

With the increase in environmental/energy investment, two awards from the Minister of Environment and improvement of environmental education system, reduced water consumption, and high rate of waste recycling rate in 2015, the Company pledges to establish green management practices through continued improvement and target management.

Environmental Accounting (EA) System

In order to ensure a more systematic analysis and operation of environmental investments aligned with its environmental management system, S-OIL has developed its own Environmental Accounting (EA) system in observance with guidelines set forth by the Korean Ministry of Environment.

The 2015 environmental accounting results show that the Company has dramatically increased investment in environment/energy over the previous year, from KRW 5.7 billion in 2014 to KRW 12.9 billion in 2015.

The company will continue to build upon those achievements, managing environmental performance in a more systematic manner.

Environmental accounting results (unit : billion won)

Environmental accounting results (unit : billion won) : Division, 2013, 2014, 2015, Remark Table.

| Division |

2013 |

2014 |

2015 |

Remark |

| Environmental cost |

164.5 |

156.5 |

154.9 |

operating costs of

post-processing facilities, etc. |

| Environmental profit |

133.0 |

125.7 |

119.8 |

energy saving and sales of environmental by-products |

| Environmental investments |

40.7 |

5.7 |

12.9 |

investing in

environmental facilities |

Environmental investment performance (unit : billion won)

Environmental investment performance (unit : billion won) : Division, 2013, 2014, 2015 Table.

| Division |

2013 |

2014 |

2015 |

| Total |

40,722 |

5,731 |

12,880 |

| air, odor, VOC |

5,565 |

678 |

4,421 |

| water quality |

3,559 |

1,413 |

1,020 |

| energy savings, technical support |

31,239 |

3,347 |

7,401 |

| soil, etc. |

359 |

293 |

38 |

Education to Enhance the Environmental Awareness

S-OIL provides environmental training to all its employees and those at partner companies on a yearly basis.

In addition to the legally mandated training programs for environmental technicians, it encourages employees to attend diverse technology seminars and holds its own seminars on environmental technologies to help better respond to external and internal environmental issues. We also offer collective training for supervisors on key environmental policies and laws.

S-OIL Environmental Management Handbook, which is the environmental training materials covering updates on environmental management and policies, is published and distributed to partner companies, significantly contributing to advancing the company’s environmental training system. The monthly newsletter facilitates sharing of environmental tips and information.

In 2015, the Company introduced the mandatory course on management of toxic substances, providing a two-hour online education to all its employees per year via the SHE system.

In 2016, we plan to further reinforce specialized education while conducting customized on-site training programs, thus enhancing employees’ awareness of environment.

Minimization of Impacts on the Environment

Given the characteristics of business, systematic measures to control pollutant emissions are necessary in the refinery industry as wide-ranging environmental issues are likely to arise concerning handling, producing, transferring and delivering of raw materials.

S-OIL’s varied measures to prevent pollutant emissions and their impact on the environment include facilities improvement, altering operation conditions, regular monitoring, emergency drills, and more. These efforts resulted in S-OIL being capable of maintaining the volume of operational pollutants far below the legal limits.

Integrated Monitoring System

As part of its preemptive green management practices, S-OIL mobilizes diverse monitoring systems to ensure the least possible impact on the environment. Established in 2012, S-OIL’s integrated monitoring system combines an atmosphere · water quality Tele-Metering System (TMS) with odor data, enabling real-time monitoring without access to a separate computing system. The dual monitoring system concurrently displays all related data on the Company’s air/water quality and odor, management and environmental issues, as well as the Company’s PR video clips and business-related video information. While allowing real-time monitoring of the Company’s environmental impact, the Integrated Monitoring System facilitates a prompt response upon detection of any abnormal signs, proof of SOIL’s strong commitment to environmental preservation.

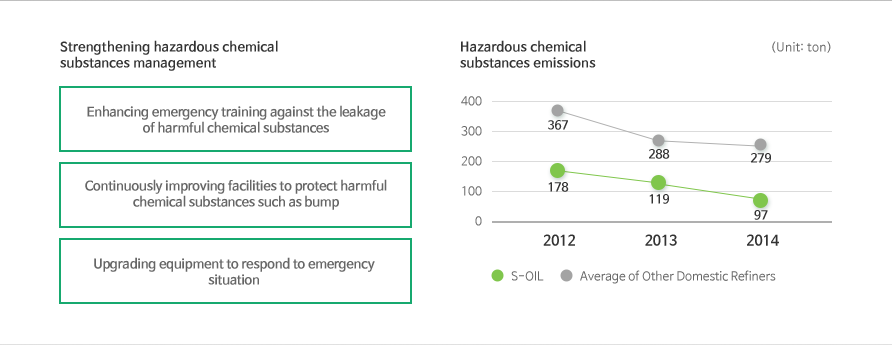

Hazardous Chemical Substances Control

S-OIL conducts a thorough and regular inspection of the entire process of manufacturing, storing, and treating chemical substances in accordance with laws and internal regulations, thereby ensuring the safety for employees and local communities.

Among others, as the Chemicals Control Act and the Act on the Registration and Evaluation, etc. of Chemical Substances entered into force in 2015 to toughen the control standards of hazardous chemicals and to systemize the management of hazards and risks of substances, S-OIL has come up with measures aimed at upgrading its chemical substance management system.

Through these efforts, S-OIL won the Minister of Environment Award in the "Presentation Contest on Cooperation of Chemical Accident Prevention" in October 2015.

Waste Control

In refining business, wastes are released from the processing of raw and subsidiary materials (crude oil and catalyst), and the amount of wastes varies depending on the revamping of facilities. S-OIL has increased its recycling rate in order to reduce waste discharge while storing waste in safe storage facilities equipped with a fire protection system. The Company will continue to do its utmost to improve the recycling rate, thus expediting the promotion of a resources-recycling society.

Air Pollutants Control

Using clean by-product gases and low-sulfur fuel oil as fuel, S-OIL has cut the emissions of sulfuric compounds (SOx). Also, in order to reduce air pollutants, we have made continued investments in environmental facilities such as Ultra Low NOx Burner and Selective Catalytic Reduction, and electrical precipitator. Furthermore, the Company adopted much stricter in-house emission standards than legally required so as to minimize HAPs (Hazardous Air Pollutants) and odorous substances that may be produced during product storage, delivery, and process treatment. In addition, S-OIL introduced the LDAR (Leak Detection and Repair) system to keep the annual leakage rate of scattering sources below 0.5%, lower than the 3% as required by law.

In 2015, we expanded the LDAR management point from the existing 130,000 to 430,000 points, efficiently innovatively reducing the leakage rate of HAPs.

In the meantime, the Ministry of Environment has enacted the Clean Air Conservation Act in order to tighten the control of hazardous air pollutants Haps emission, laying out the standards for facility management. In response, S-OIL has set up in-house management standards for facilities improvement.

Water Quality Control

S-OIL has strived to reduce waste discharge while increasing the recycling rate to create a virtuous circle of eco-friendly resources. We have maintained a high rate of waste recycling by strictly practicing separate waste collection. In 2015, S-OIL participated in the "Industrial sectors' Declaration for Sustainable Korea 2030," affirming its strong commitment to enhancing the nation's resources circulation and resources productivity. We will continue to invest in technology development to improve the recycling rate.

Prevention of Oil and Hazardous Chemical Substance Leakage

◆ Prevention of Leakage on Land

S-OIL has systematic response procedures to prevent leakage of hazardous chemical substances on land under which facilities are subject to regular inspection and drills are held to beef up emergency response capabilities.

S-OIL takes environmental investment seriously. One case in point is oil sensors we installed step by step to counter emergency situations with speed. In 2015, we upgraded the existing department-level drills to Refinery-wide response exercises based on a scenario of chemical leakage into the river.

Efforts to advance emergency drills will remain no less strong as we plan to develop wide range of scenarios on leakages based on which to build on response manuals and bolster private-public emergency drills.

◆ Prevention of Leakage into the Sea

S-OIL operates a Vetting System which bars vessels that fall short of strict safety standards from entering port facilities. Under the system, all vessels are evaluated of their risk factors and only double-hulled tankers* are permitted into the port in order to minimize risk of oil spill resulting from vessel accidents. Tugboats are used to aid berthing of small-sized tankers and a protection system (radar, tidal current measurement system, and mooring tension measurement system) is built into SPM (Single Point Mooring), which is the onshore mooring facilities for VLCCs.

In the first half of 2015, we upgraded the existing system by introducing a 24-hour monitoring system that issues an accident alert around the pier and SPM, lowering the likelihood of any subsequent vessel accidents. And in the second half, we organized the Oil Spill Free TFT with the mission to lower vessel accidents to "zero" and identified 27 improvement tasks.

Based on the improvement tasks, we have a plan to set up emergency shut-down valves on SPM hoses by 2017 as part of the continuous investment in anti-leakage solutions, thereby protect the marine environment.

Environmental Impact Assessment

S-OIL has developed into an eco-friendly corporate that duly complies with ‘Environmental Impact Assessment Act’ while taking into consideration its impact on local communities. For new project or major construction undertaking, the company commissions a specialized environmental impact assessment firm to monitor our impact on air, water, ecology, and soil on a regular basis. The assessment report on a new project is presented to relevant authorities. The company carries out post-environmental impact assessment in observance with laws during and after construction, ensuring to minimize environmental impact.

Environmental Management Reaching out to Communities

Amid the growing environmental accidents in the nation, the Korean government toughens regulations and penalties on companies’ environmental issues. Social concerns over environmental responsibilities of businesses are mounting as well. S-OIL ensures that all its environmental facilities are up to the highest level of reliability while implementing various measures aimed at achieving the voluntary pollutant discharge reduction to respond stakeholders’ expectations.

Additionally, the company continuously enhances its environmental management practices through facility improvement and stricter maintenance and at the same time proactively responds to enactments and revisions of environmental regulations. S-OIL is making every effort to adhere to environmental management as it maintains diverse communication channels with stakeholders to make sure their thoughts do not go unheard. Amid the growing environmental accidents in the nation, the Korean government toughens regulations and penalties on companies’ environmental issues. Social concerns over environmental responsibilities of businesses are mounting as well. S-OIL ensures that all its environmental facilities are up to the highest level of reliability while implementing various measures aimed at achieving the voluntary pollutant discharge reduction to respond stakeholders’ expectations.

Additionally, the company continuously enhances its environmental management practices through facility improvement and stricter maintenance and at the same time proactively responds to enactments and revisions of environmental regulations. S-OIL is making every effort to adhere to environmental management as it maintains diverse communication channels with stakeholders to make sure their thoughts do not go unheard.

Compliance with Environmental Regulations

In a preemptive response to environmental regulations, S-OIL puts forward ‘Preemptive Green Management’. The company has pursued environmental management as it introduced optimal preventive facilities from the initial stage of plant construction. We commit to minimizing environmental impact from its business activities by strictly observing environmental regulations and adopting rigorous in-house standards. In particular, we keep reinforcing a voluntary environmental management system by conducting daily inspections and taking prompt correctional measures or reviews of inadequacies identified.

Voluntary Environmental Management Agreement

An ardent champion for the Korean government’s environmental policies, S-OIL has signed a number of Voluntary Agreements (VA) on soil pollution prevention, air pollutant reduction, green purchases and other environmental initiatives as part of its strong commitment to environmental preservation.

In 2014, the company exceeded the air pollutant reduction goal as it cut 16% of pollutants compared to the base year by duly complying with the second VAs on air pollutants reduction while undertaking facilities improvement and fuel conversion.

-

VA for land

environment

preservation

2013 ~ 2023

Refine land pollution and execute land pollution test on own at an interval of within 3 years

-

Self-Environment

Management Con-

tract for 2nd Air

Pollution Substance

2012 ~ 2016

Air pollution substance discharge amount reduced by 16% for dust, So2, NOx, and VOC compared to standard year (2008)

-

Self-Environment

Management

Contract for reduc-

tion of chemical

substance discharge

2013 ~ 2017

Benzene discharge amount reduced by around 31% in contrast to standard year

-

VA for environment-

ally friendly purchase

in the industry

2005 ~ 2016

Production, Liquidity, and Purchase Promotion Activation of Green Products

-

Contract for Joint

Promotion in

Korean Auto-Oil

Program

2011 ~ 2015

Government for the reduction of air pollution and greenhouse gas due to vehicle discharge – Automobile industry –Promote joint research business between fuel companies.

Addressing Environmental Complaints

Upon reception of any complaints on environmental issues related to our Ulsan refinery, S-OIL promptly visits the site and address the issue. All questions and inquiries made to the Head Office regarding the company’s environmental policies are answered via e-mail or phone. While adopting an odor monitoring system for the systematic control of odors - a frequent subject of complaints at our refineries and plants - the company discloses objective data to claimants and takes appropriate measures in consideration of the wind direction and weather conditions to effectively locate the sources of odor. When it is required for environmental management practices, related stakeholders are invited to visit the site in person, which also serves as an opportunity to communicate with people on its outstanding environmental management practices.